The Xhorse Dolphin XP005L is designed for precision, convenience, and versatility. With its advanced M5 clamp and calibration features, users can ensure accurate key cutting right from the start. This guide walks you through the complete setup process.

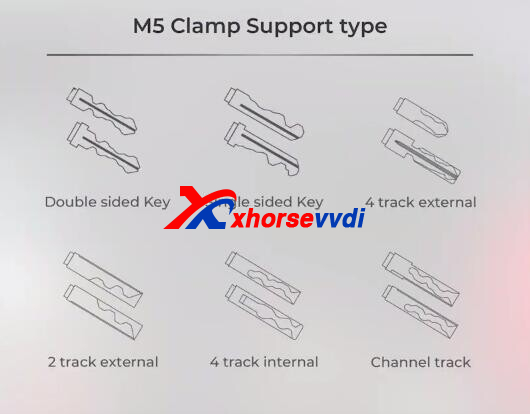

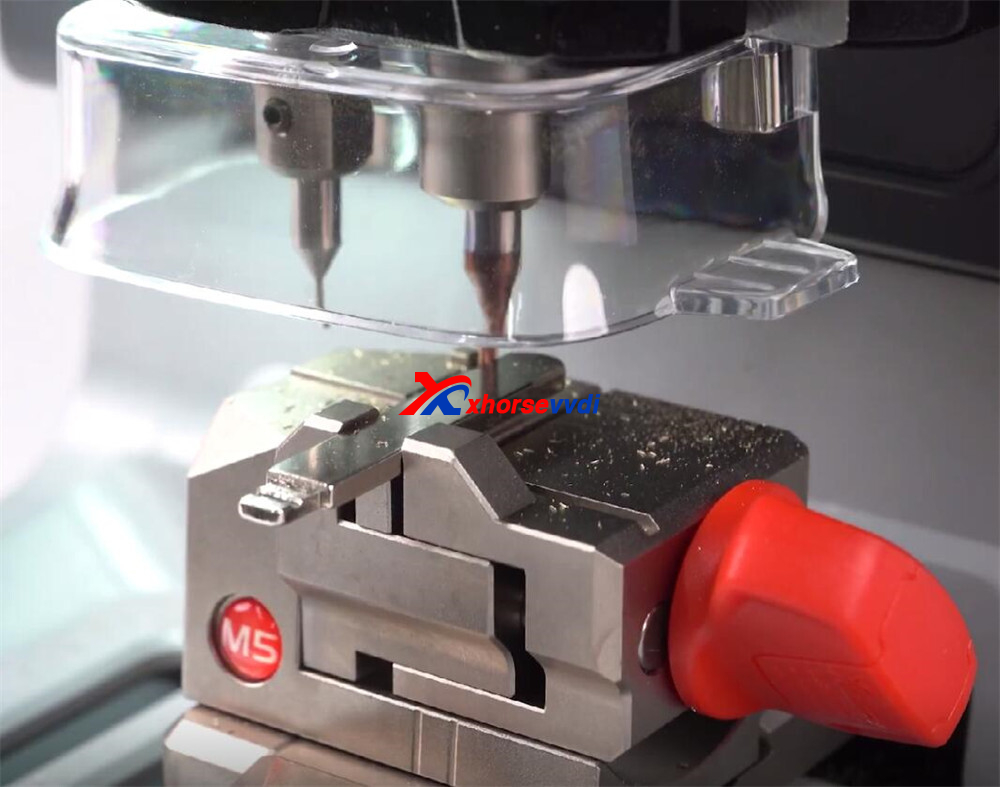

Step 1: Understand the M5 Clamp

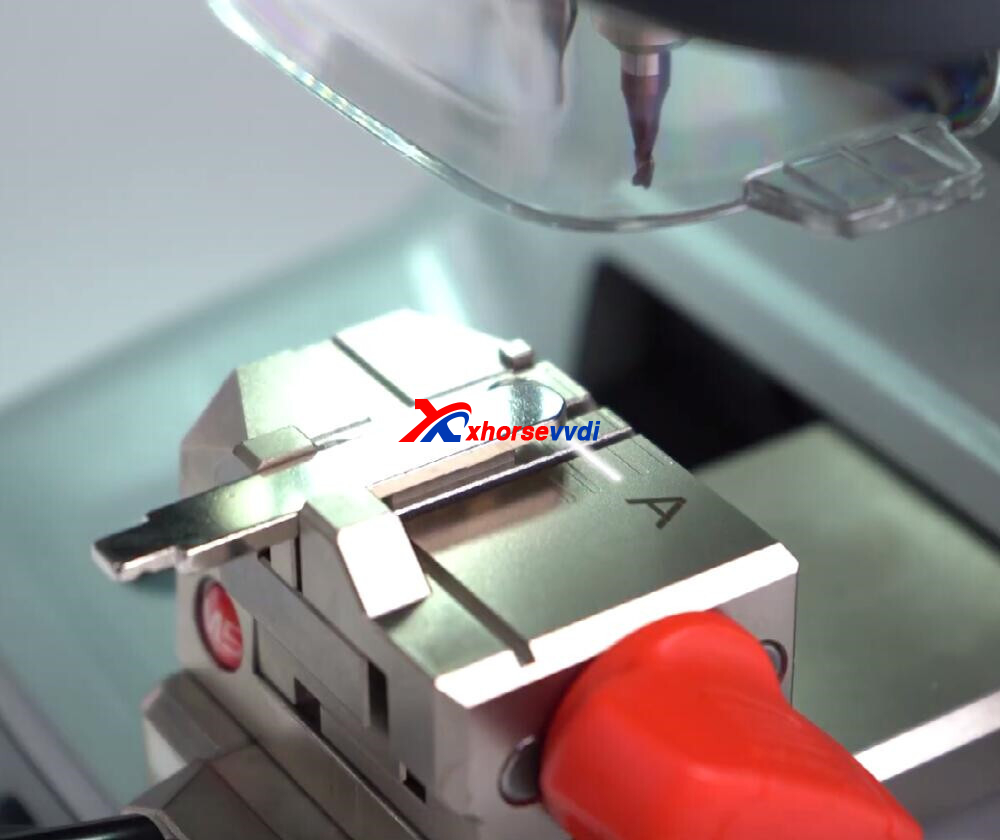

The Dolphin XP005L comes with the upgraded M5 clamp, which features dual sides (A and B).

- To switch sides, simply loosen the adjustment knob, rotate the clamp, and secure it again.

- This dual design makes it compatible with a wide range of key types.

Supported key types:

- Double-sided keys

- Single-sided keys

- 4-track external

- 2-track external

- 4-track internal

- Channel track

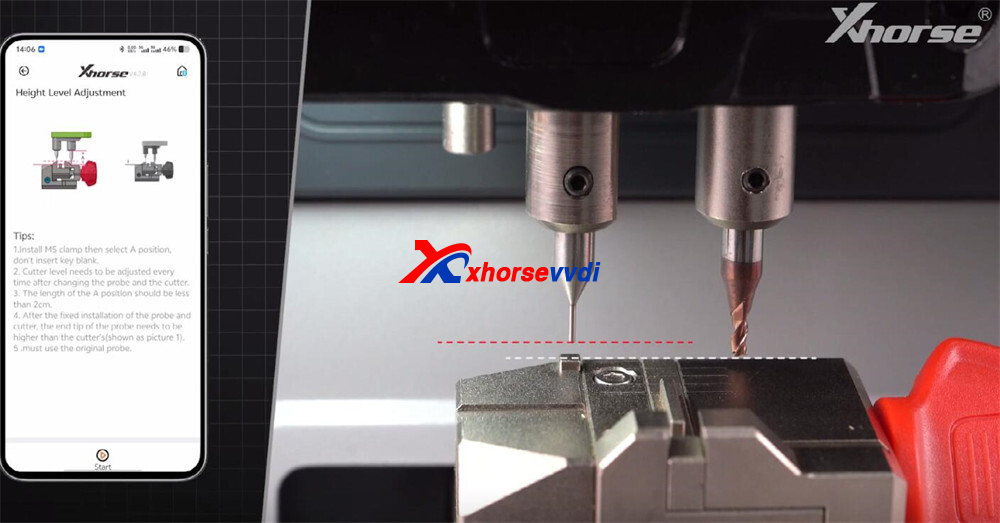

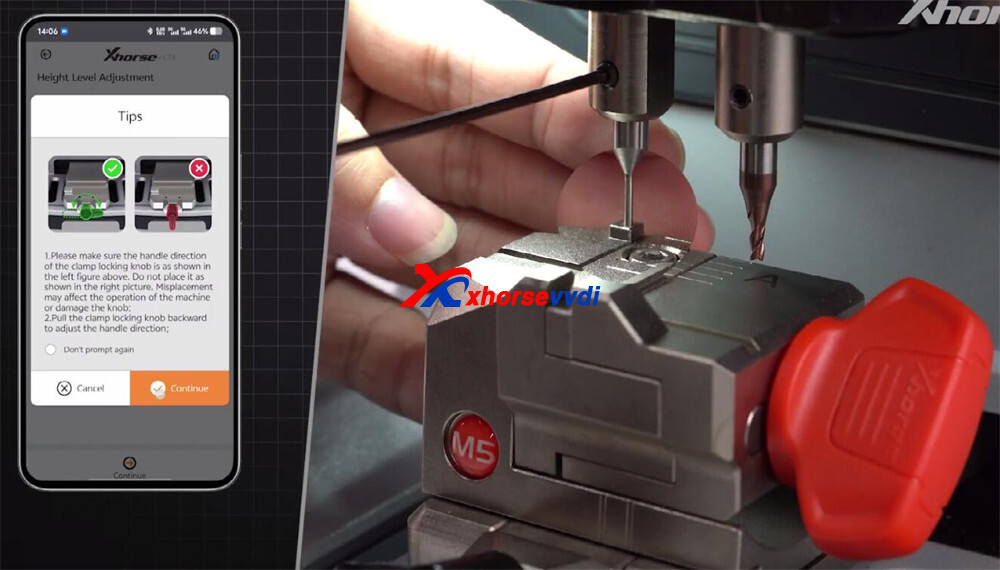

Step 2: Calibration Setup

Accurate calibration is essential before cutting any key.

1.Height Level Adjustment

- Navigate to Parameter → Height Level Adjustment.

- Ensure the cutter tip sits slightly higher than the probe tip.

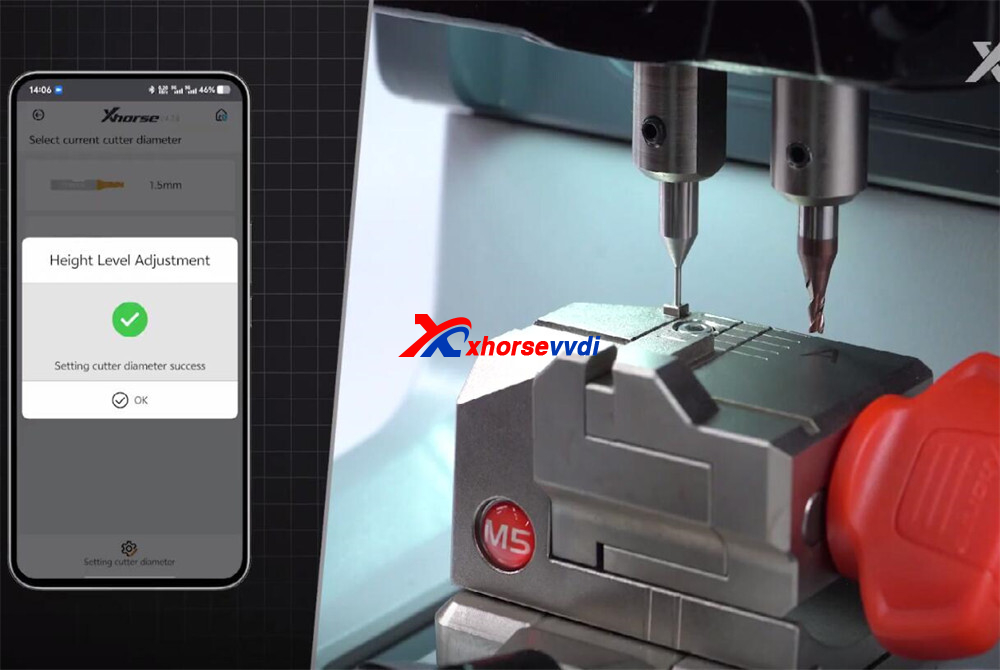

2.Cutter and Probe Calibration

- Select the 2.5mm cutter diameter.

- Calibrate the probe height.

3.Test Cut Calibration

- Insert a blank key into the clamp (Side A).

- Align the top of the key to line three.

- Run the calibration test cut.

- Remember to brush away debris during cutting for a smooth process.

Step 3: Finalizing the Setup

Once the calibration test cut is complete:

- Proceed with the final cutting calibration.

- The machine will now be properly leveled and aligned for precise cutting.

After following these steps, your XP005L Key Cutting Machine is fully set up and ready for use. From clamp positioning to test cut calibration, every step ensures the machine delivers accurate, reliable, and professional-quality key cutting results.

Video Guide:

Skype: xhorsevvdi.com

Whatsapp: https://wa.me/8613983756354

Whatsapp:

Whatsapp:

Skype:

Skype: